C.S. SIMMONS ENGINEERING LTD

Mill Road Trading Estate

Radstock, Bath BA3 5TX

Mill Road Trading Estate

Radstock, Bath BA3 5TX

Tel: +44 (0)1761 433944

Fax: +44 (0)1761 437901

Email: mail@cssimmons.co.uk

Fax: +44 (0)1761 437901

Email: mail@cssimmons.co.uk

Capacity List

Adobe pdf version of this page for easy printing, saving or emailing (~1.6MB)

GENERAL DESCRIPTION OF SPECIALIST SERVICES

C.S. Simmons Engineering provide a CNC machining service to many industries, including oil, valve and defence. All types of machining are undertaken, including heavy stainless steel machining and machining of exotic materials such as Inconel, Hastelloy, Monel, 17-4 PH, S316 Super Duplex, Zeron 100 and Waspalloy.*

Manufacture and inspection meet the requirements of the updated BS EN ISO 9001 : 2015 certification (Certificate can be provided on request).

Quality and performance are monitored closely with set procedures and with Tricorn Job Processing software that allows unparalleled traceability during the machining process and long after delivery.

C. S. Simmons Engineering continually invests in the latest CNC precision machining technology available to always remain very competitive and to be able to meet very demanding delivery times without compromising quality.

MAIN SERVICES OFFERED

CS Simmons Engineering provide Large Component, Complex Component, Prototype Component, and Reverse Engineering CNC Precision Machining Services in both Regular and Super Alloys. Specific precision machining services include CNC Turning, CNC Machining, CADCAM Design and CNC CMM Inspection.

QUALITY APPROVALS

C.S. Simmons Engineering is a BS EN ISO 9001 : 2015 Quality Management Certified Firm, Certificate No. 9835, and are audited by NQA. (Certification has been held for 9 years.)

Vertical Machining Centre (CNC)

Hartford HCMC-2082AG

Single Table Open Fronted Vertical Machining Centre, with hardened & ground box guideways for heavy cutting capabilities. FANUC 0iMD CNC Control System.

X-axis 1800mm

Y-axis 920mm

Z-axis 700mm

Table 2000mm x 920mm

Table Load 3000kg

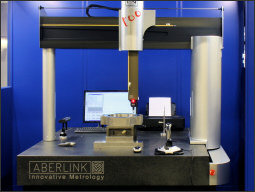

CNC CMM INSPECTION

Aberlink Zenith Too 1000 CNC CMM

Various inspection reports are available with the Zenith Too 1000 CNC CMM, from dimensioned graphical representations to tabulated reports showing nominals, tolerances, errors, pass/fails, geometric tolerances, etc., that may also be output to an Excel spreadsheet.

Measurement Volume:

— X-axis 1000mm; Y-axis 1000mm; Z-axis 600mm

Accuracy: B89: 0.008/300mm; VDI(U3): 0.0038 + L/250

Machining Centre (CNC)

Doosan Heavy Duty HM 630

The HM 630 combines a high torque spindle drive and powerful axis drives for a large chip removal rate. The massive meehanite cast structure and wrap around box guideways provide the rigidity required for both heavy cutting and superb surface finishes. Fanuc 18i-MB controls.

Max Diameter — 1000mm

Height Z-axis — 1000mm

Max Weight — 1200kg

Sawing (Vertical Band) Throat — 350mm

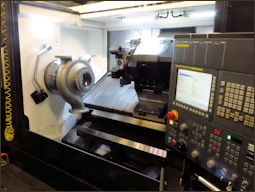

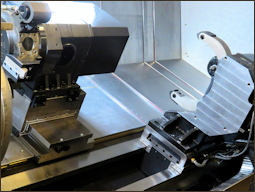

Turning Centre (CNC)

CNC Puma 12L

High response turning centre with FAPT conversational programming with Fanuc 15TA system. Fully programmable tailstock.

Length Z-axis — 1100mm

Chuck Dia. — 400mm

Max Chucking Dia. — 580mm

Turning Centre (CNC)

CNC Puma 10HC Lathe with Fanuc OT-C controls.

Fully programmable tailstock.

Length Z-axis — 450mm

Chuck Dia. — 250mm

Max Chucking Dia. — 280mm

Turning Centre (CNC)

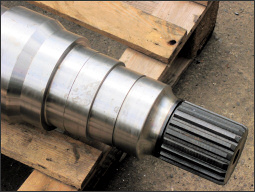

Hyundai-Wia L500LMA CNC Turning Centre equipped with Fanuc 18i Control System and

Steady Rest Type RX-5-Z 75-430

(Workpiece: 430mm max. dia. – 30mm min. dia.)

Maximum Turning Diameter — 690mm

Live Tools ER40 (03-025mm Tool Fitting / 140 N Maximum Torque)

Length Z-axis 2500mm (maximum workpiece length, ideal for machining long shafts accurately)

Chuck diameter — 24"

Maximum swing over bed — 1030mm

Turning Centre (CNC)

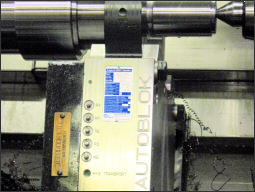

Daewoo Puma 400LA CNC Turning Centre equipped with Fanuc 18i control system. Fully programmable tailstock. Fully retrofitted SMV Autoblock steady (Workpeice: 230mm max. dia. – 30mm min. dia.)

Maximum Turning Diameter — 580mm

Length Z-axis 2200mm (max workpiece length, ideal for machining long shafts accurately)

Chuck Dia(IN) — 18"

Max swing over bed — 800mm

Machining Centre (CNC)

CNC “Hartford Kappa VMC130”

4 Axis, Fully programmable 4th ‘B’axis. ‘Hartrol’ programming system with Fanuc 18i controls. Thermal heat dissipation. High pressure through coolant. Many macro functions to reduce programming set up times.

Length X-axis — 1500mm

Width Y-axis — 700mm

Height Z-axis — 800mm

Splining

Manual Machines

Ormerod Slotter - with 250mm stroke, cuts keyways along the length of a bore.

Tarnow Centre Lathe - New arrival bought specifically for machining 1 off items of large size. Solid Cast Bed construction, digital readout and positioning capabilities.

Length Z-axis — 2000mm

Chuck Dia. — 500mm

Max Chuck Dia. — 750mm

Gang Drills - 2 sets for finishing operations, i.e., drilling, tapping, reaming & deburring.

C.S. Simmons Engineering provide a CNC machining service to many industries, including oil, valve and defence. All types of machining are undertaken, including heavy stainless steel machining and machining of exotic materials such as Inconel, Hastelloy, Monel, 17-4 PH, S316 Super Duplex, Zeron 100 and Waspalloy.*

Manufacture and inspection meet the requirements of the updated BS EN ISO 9001 : 2015 certification (Certificate can be provided on request).

Quality and performance are monitored closely with set procedures and with Tricorn Job Processing software that allows unparalleled traceability during the machining process and long after delivery.

C. S. Simmons Engineering continually invests in the latest CNC precision machining technology available to always remain very competitive and to be able to meet very demanding delivery times without compromising quality.

MAIN SERVICES OFFERED

CS Simmons Engineering provide Large Component, Complex Component, Prototype Component, and Reverse Engineering CNC Precision Machining Services in both Regular and Super Alloys. Specific precision machining services include CNC Turning, CNC Machining, CADCAM Design and CNC CMM Inspection.

QUALITY APPROVALS

C.S. Simmons Engineering is a BS EN ISO 9001 : 2015 Quality Management Certified Firm, Certificate No. 9835, and are audited by NQA. (Certification has been held for 9 years.)

Vertical Machining Centre (CNC)

Hartford HCMC-2082AG

Single Table Open Fronted Vertical Machining Centre, with hardened & ground box guideways for heavy cutting capabilities. FANUC 0iMD CNC Control System.

X-axis 1800mm

Y-axis 920mm

Z-axis 700mm

Table 2000mm x 920mm

Table Load 3000kg

CNC CMM INSPECTION

Aberlink Zenith Too 1000 CNC CMM

Various inspection reports are available with the Zenith Too 1000 CNC CMM, from dimensioned graphical representations to tabulated reports showing nominals, tolerances, errors, pass/fails, geometric tolerances, etc., that may also be output to an Excel spreadsheet.

Measurement Volume:

— X-axis 1000mm; Y-axis 1000mm; Z-axis 600mm

Accuracy: B89: 0.008/300mm; VDI(U3): 0.0038 + L/250

Machining Centre (CNC)

Doosan Heavy Duty HM 630

The HM 630 combines a high torque spindle drive and powerful axis drives for a large chip removal rate. The massive meehanite cast structure and wrap around box guideways provide the rigidity required for both heavy cutting and superb surface finishes. Fanuc 18i-MB controls.

Max Diameter — 1000mm

Height Z-axis — 1000mm

Max Weight — 1200kg

Sawing (Vertical Band) Throat — 350mm

Turning Centre (CNC)

CNC Puma 12L

High response turning centre with FAPT conversational programming with Fanuc 15TA system. Fully programmable tailstock.

Length Z-axis — 1100mm

Chuck Dia. — 400mm

Max Chucking Dia. — 580mm

Turning Centre (CNC)

CNC Puma 10HC Lathe with Fanuc OT-C controls.

Fully programmable tailstock.

Length Z-axis — 450mm

Chuck Dia. — 250mm

Max Chucking Dia. — 280mm

Turning Centre (CNC)

Hyundai-Wia L500LMA CNC Turning Centre equipped with Fanuc 18i Control System and

Steady Rest Type RX-5-Z 75-430

(Workpiece: 430mm max. dia. – 30mm min. dia.)

Maximum Turning Diameter — 690mm

Live Tools ER40 (03-025mm Tool Fitting / 140 N Maximum Torque)

Length Z-axis 2500mm (maximum workpiece length, ideal for machining long shafts accurately)

Chuck diameter — 24"

Maximum swing over bed — 1030mm

Turning Centre (CNC)

Daewoo Puma 400LA CNC Turning Centre equipped with Fanuc 18i control system. Fully programmable tailstock. Fully retrofitted SMV Autoblock steady (Workpeice: 230mm max. dia. – 30mm min. dia.)

Maximum Turning Diameter — 580mm

Length Z-axis 2200mm (max workpiece length, ideal for machining long shafts accurately)

Chuck Dia(IN) — 18"

Max swing over bed — 800mm

Machining Centre (CNC)

CNC “Hartford Kappa VMC130”

4 Axis, Fully programmable 4th ‘B’axis. ‘Hartrol’ programming system with Fanuc 18i controls. Thermal heat dissipation. High pressure through coolant. Many macro functions to reduce programming set up times.

Length X-axis — 1500mm

Width Y-axis — 700mm

Height Z-axis — 800mm

Splining

Manual Machines

Ormerod Slotter - with 250mm stroke, cuts keyways along the length of a bore.

Tarnow Centre Lathe - New arrival bought specifically for machining 1 off items of large size. Solid Cast Bed construction, digital readout and positioning capabilities.

Length Z-axis — 2000mm

Chuck Dia. — 500mm

Max Chuck Dia. — 750mm

Gang Drills - 2 sets for finishing operations, i.e., drilling, tapping, reaming & deburring.

NEW

HYUNDAI-WIA

L500LMA

TURNING

CENTRE

2019

HYUNDAI-WIA

L500LMA

TURNING

CENTRE

2019

MAXIMUM CAPACITIES:

Vertical Milling

X = 1800.0mm

Y = 0920.0mm

Z = 0700.0mm

X = 1800.0mm

Y = 0920.0mm

Z = 0700.0mm

Horizontal Milling

X = 1000.0mm

Y = 1000.0mm

Z = 1000.0mm

X = 1000.0mm

Y = 1000.0mm

Z = 1000.0mm

CNC Turning

Diameter = 800.0mm

Swing = 1030.0mm

Between Centres = 2500.0mm

Hydraulic steady units, programmable

Diameter = 800.0mm

Swing = 1030.0mm

Between Centres = 2500.0mm

Hydraulic steady units, programmable

CMM Inspection

X = 1000.0mm

Y = 1000.0mm

Z = 0650.0mm

X = 1000.0mm

Y = 1000.0mm

Z = 0650.0mm

* All trademarks, logos and serviced marks mentioned on this website are the trademarks or service marks of their respective owners. In particular, Monel and Inconel are

* registered trademarks of Inco Alloys/Special Metals, Hastelloy is a registered trademark name of Haynes International, Inc., 17-4 PH is a registered trademark of AK Steel

* Corporation, Zeron is a registered trademark of Weir Materials & Foundries and Waspalloy is a registered trademark of United Technologies.

* registered trademarks of Inco Alloys/Special Metals, Hastelloy is a registered trademark name of Haynes International, Inc., 17-4 PH is a registered trademark of AK Steel

* Corporation, Zeron is a registered trademark of Weir Materials & Foundries and Waspalloy is a registered trademark of United Technologies.

Adobe pdf version of this page for easy printing, saving or emailing (~1.4MB)

NEW

STEADY REST TYPE

RX-5-Z 75-430

2019

STEADY REST TYPE

RX-5-Z 75-430

2019

Certificate

No. 9835

No. 9835

HARTFORD

HCMC-

2082AG

VERTICAL

MACHINING

CENTRE

HCMC-

2082AG

VERTICAL

MACHINING

CENTRE

DOOSAN

HEAVY

DUTY

HM 630

HEAVY

DUTY

HM 630

ABERLINK

ZENITH

TOO 1000

CNC CMM

ZENITH

TOO 1000

CNC CMM

C. S. SIMMONS ENGINEERING LTD

CNC PRECISION MACHINING OF HIGH-PERFORMANCE AND SUPER ALLOYS TO 2.5M LENGTH, 0.8M DIAMETER AND 1.2M CUBED

REGISTERED OFFICE: MILL ROAD INDUSTRIAL TRADING ESTATE, FROME HILL, RADSTOCK, BATH, SOMERSET, ENGLAND BA3 5TX | COMPANY NO. 01253963

TEL: +44 (0)1761 433944 | FAX: +44 (0)1761 437901 | CONTACT US | EMAIL: SALES@CSSSIMMONS.CO.UK | WEB: WWW.CSSIMMONS.CO.UK

TOP OF PAGE | HOME | ABOUT US | MARKETS | BROCHURE | FIND US | CONTACT US | SITE MAP | MANUFACTURING SERVICES | SPECIALIST MATERIALS | 2.5M LENGTHS

LARGE COMPONENT MACHINING | 1.2 METRE CUBED MACHINING CAPACITY | COMPLEX COMPONENT MACHINING | PROTOTYPE CNC MACHINING | CNC MACHINED CASTINGS

REVERSE ENGINEERING | WELDING | PRODUCTION CONTROL | QUALITY | OUR FACTORY | CAPACITY LIST | DOWNLOADS | VACANCIES | LINKS | LEGAL | COOKIE POLICY

Website by www.practicalservices.co.uk | © Copyright 2008-2021 C.S. Simmons Engineering Ltd

CNC PRECISION MACHINING OF HIGH-PERFORMANCE AND SUPER ALLOYS TO 2.5M LENGTH, 0.8M DIAMETER AND 1.2M CUBED

REGISTERED OFFICE: MILL ROAD INDUSTRIAL TRADING ESTATE, FROME HILL, RADSTOCK, BATH, SOMERSET, ENGLAND BA3 5TX | COMPANY NO. 01253963

TEL: +44 (0)1761 433944 | FAX: +44 (0)1761 437901 | CONTACT US | EMAIL: SALES@CSSSIMMONS.CO.UK | WEB: WWW.CSSIMMONS.CO.UK

TOP OF PAGE | HOME | ABOUT US | MARKETS | BROCHURE | FIND US | CONTACT US | SITE MAP | MANUFACTURING SERVICES | SPECIALIST MATERIALS | 2.5M LENGTHS

LARGE COMPONENT MACHINING | 1.2 METRE CUBED MACHINING CAPACITY | COMPLEX COMPONENT MACHINING | PROTOTYPE CNC MACHINING | CNC MACHINED CASTINGS

REVERSE ENGINEERING | WELDING | PRODUCTION CONTROL | QUALITY | OUR FACTORY | CAPACITY LIST | DOWNLOADS | VACANCIES | LINKS | LEGAL | COOKIE POLICY

Website by www.practicalservices.co.uk | © Copyright 2008-2021 C.S. Simmons Engineering Ltd

1 off to 100 off batches

Lean manufacturing

methods employed

Quality certifications

& approvals (Please ask)

ASTM compliant

welding services

Extensive capacity

Quick turnaround

(Try us, we like a challenge)

Same day competitive

quotations

Job processing software

for traceability before,

during & after machining

Peace of mind for you

Lean manufacturing

methods employed

Quality certifications

& approvals (Please ask)

ASTM compliant

welding services

Extensive capacity

Quick turnaround

(Try us, we like a challenge)

Same day competitive

quotations

Job processing software

for traceability before,

during & after machining

Peace of mind for you

L - Low Lead Times

E - Extremely Competitive

A - Accurate

N - NQA Approval

N - BS EN ISO

N - 9001 : 2015

N - Certification

E - Extremely Competitive

A - Accurate

N - NQA Approval

N - BS EN ISO

N - 9001 : 2015

N - Certification